Description

About this item

- 【EXCELLENT PERFORMANCE】 - The handled induction sealer machine adopts electromagnetic induction heating, sealing the bottle efficiently. It can seal bottles with various capsizes from 20 mm to 100 mm. The sealer's sealing power is 500W, which can be adjusted according to the demand.

- 【DIGITAL CONTROL】 - The electromagnetic induction sealing machine is operated through a simple control panel. You can easily adjust the sealing time and working power. It can achieve zeroing by pushing the zeroing key for 2 seconds. Besides, the sealing time and production volume can be visible through two displays.

- 【POWER-OFF MEMORY】 - The handheld heat induction sealer is constructed of a thick copper induction coil, making the equipment run more efficiently with low power consumption. The volume and time will not be lost after the machine is powered off or restarted.

- 【SECURITY PROTECTION】 - A separate power switch guarding against electric shock and is securer to use. The induction heat sealing machine features automatic overheating, over-voltage, and over-current protection functions. In addition, it is equipped with cooling parts to help heat dissipation.

-

【FAR-RANGING USAGE】 - Our induction heat sealer machine is applied to the sealing of non-metallic containers such as plastic bottles and glass bottles on the market, like ABS, PE (HDPE, LDPE), PET, PP, PS, PVC.

- Specifications

- Model: GLF-500

- Seal Diameter: Φ0.79-3.94 inch/20-100 mm

- Capacity: 5-20 pcs/min

- Working Ambient Temp: 25-45℃

- Output Power: 500W

- Work Frequency: 80KHz(±20%)

- Relative Humidity(RH): ≤95%

- Item Weight: 8.8 lbs/4 kg

- Item Dimension: 13.5x11 x5.5 in/34.3x27.9x14 cm

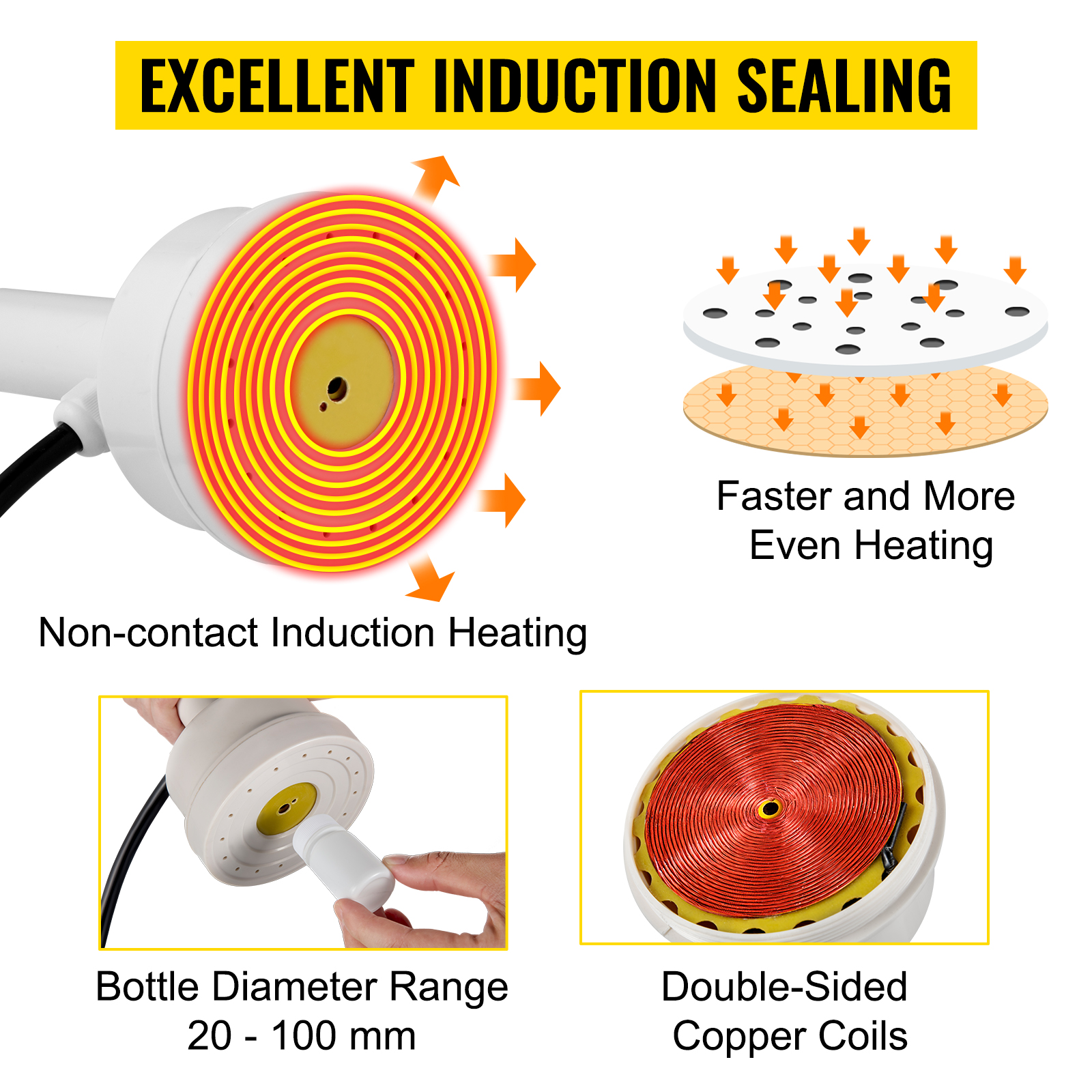

Excellent Induction Sealing

Through non-contact induction heating, the foil cap can be adequately sealed with no leakage. In addition, the double-sided copper coils provide faster and more even heating while consuming less energy.

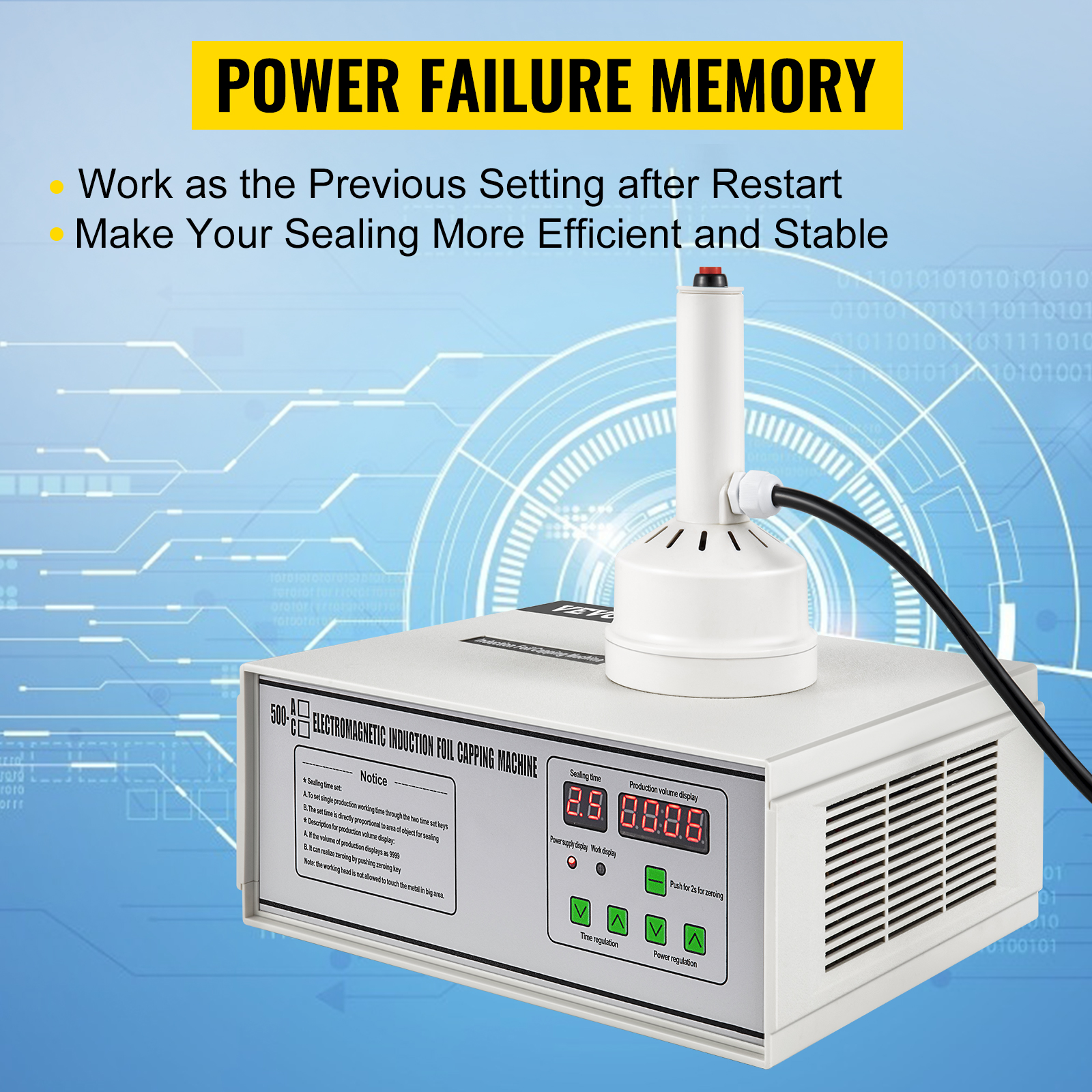

Power Failure Memory

The volume and time will not be lost after the induction sealer is powered off or restarted. This bottle cap sealer can work as the previous setting, making your sealing more efficient and stable.

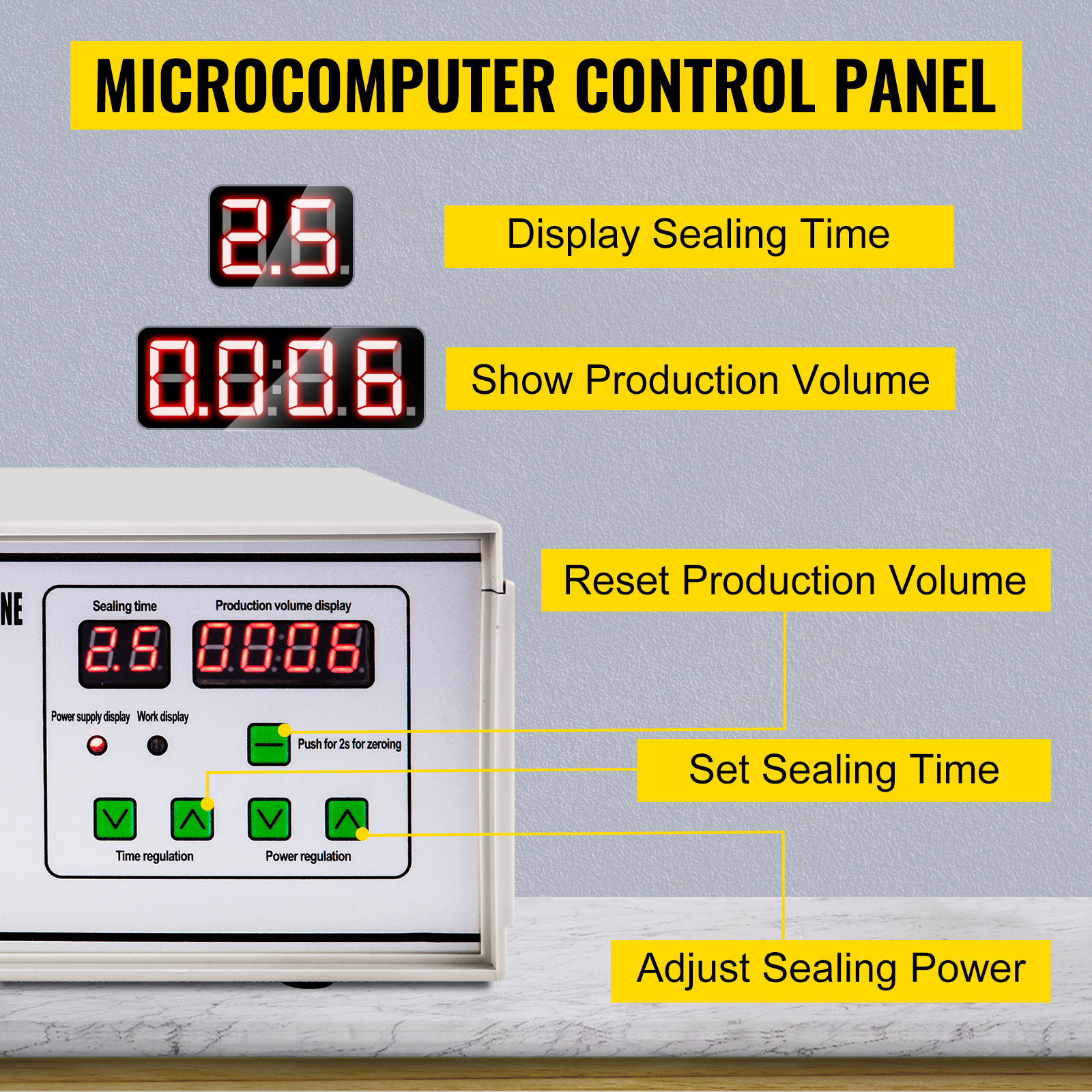

Microcomputer Control Panel

Our induction sealing machine's power and sealing time can be adjusted by relative buttons and displayed on digital screens. And the zeroing button can be pushed for 2 s to reset the count.

Vertical Inductive Switch

An independent inductive switch is designed for controlling the sealing process, which is sensitive and easy to replace and repair. In addition, the electric shock design makes our induction sealer machine securer to use.

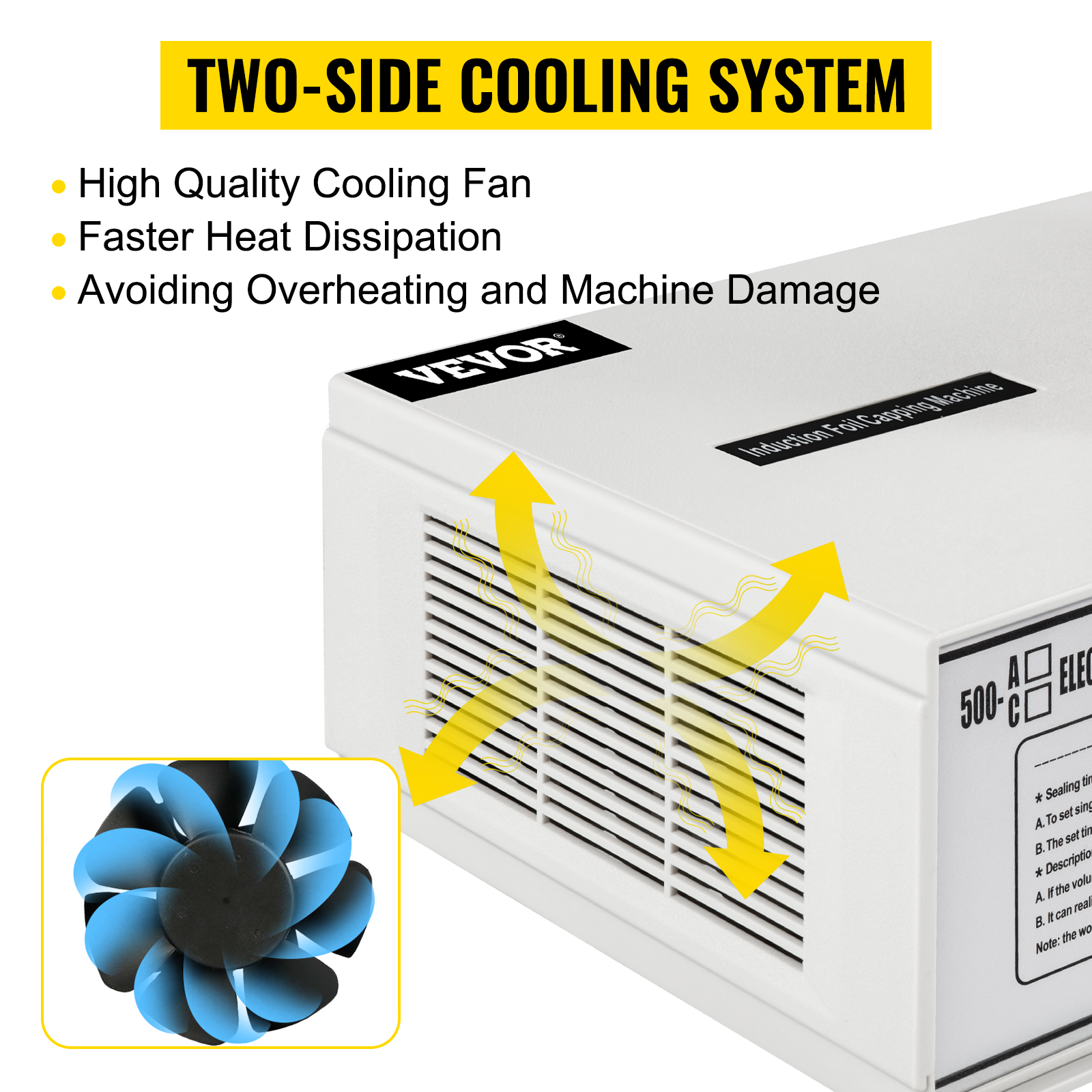

Two-side Cooling System

Our cap sealing machine is equipped with a high-quality heat dissipation system, which allows the sealer for long working hours and avoids overheating thanks to the multiple machine protection.

Wide Application

Our induction bottle cap sealer is widely used in pharmaceutical, Chemical, food, beverage, cosmetics, and other industries, suitable for sealing glass and non-metallic bottles.