Description

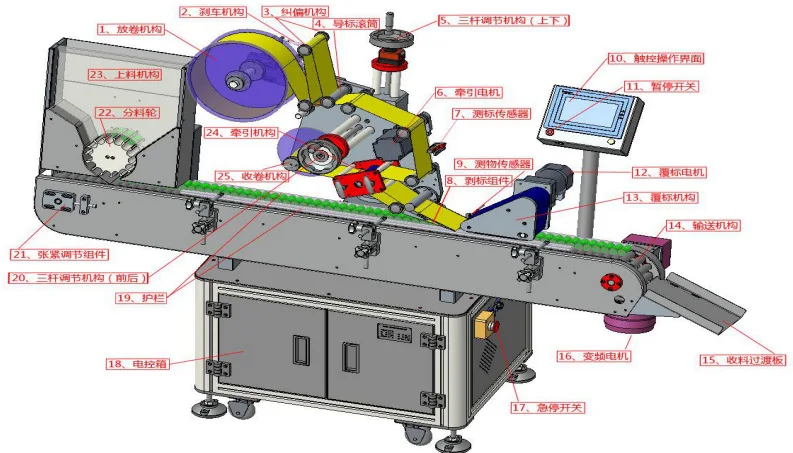

YTK-330 automatic vertical round bottle positioning labeling machine

Usage Instructions

This machine is a horizontal labeling machine. Suitable for circumferential or semi-circular labeling of cylindrical objects with small diameters that are not easy to stand. Horizontal transfer and horizontal labeling are used to increase stability and labeling efficiency is very high. Widely used in cosmetics, food, medicine, chemicals, stationery, electronics, hardware, toys, plastics and other industries. Such as: lipstick, oral liquid bottle, small medicine bottle, ampoule, syringe bottle, test tube, battery, ham, sausage, test tube, pen, etc.

Features

High-speed bottle separation, low bottle breaking rate: flexible three-axis import labeling mechanism, good labeling effect and high efficiency; adopting new vertical hopper automatic bottle dividing mechanism, applying flexible bottle-diving technology and flexible coating technology to effectively eliminate The bottleneck caused by the error of the bottle itself is not smooth, and the stability is improved;

Adapted to many products: This model is mainly for all kinds of small-diameter bottle horizontal labeling, vertical hopper horizontal roller conveyor labeling, conveyor chain tilt, bottle automatic correction, flexible labeling, three-point positioning method Labeling accuracy, with automatic splitting function, can be adapted to the appropriate size or non-standard according to the size and characteristics of the labeling product;

Wide range of labeling: metal, glass, plastic pet and other materials can be adapted; self-adhesive labels, self-adhesive film, electronic supervision code, barcode, QR code labels, etc.;

Accurate labeling and high stability: labeling speeds up to 280 bottles per minute. Greatly save manpower and material resources to improve efficiency; use plc+ subdivided stepper motor to drive accurate bidding; adopt cam-type brake mechanism, uniform tension, reduce label breakage, ensure accurate inspection; standard belt bypass correction mechanism can prevent label left and right Offset to ensure the accuracy of the bidding;

Powerful, multi-functional configuration: automatic photoelectric tracking, with no material and no labeling, no standard automatic calibration and automatic label detection to prevent leakage and waste; according to the actual situation of the customer, you can choose one-machine operation or docking production line.

Intelligent control, simple operation: PLC programming control, color large touch screen operation, Chinese and English operable interface, convenient and intuitive, powerful data memory function, can store 50 sets of labeling parameters, easy and fast operation, with fault prompts and help functions;

The side mark and the measuring object use the imported first-line brand sensor: high detection sensitivity, stable performance and durability; convenient production management: with labeling technology, power saving mode, photoelectric tracking label and other functions, production management is easier.

Product parameters

|

Labeling accuracy |

±1mm |

|

Labeling speed |

100-280Pieces/minute |

|

Product specifications |

Diameter:15-60mm;high:30-90mm |

|

Label specification |

L:20-90mm;w:15-90mm |

|

Reference Size |

2200*1065*1600mm |

|

power supply |

220v50hz |

|

power |

1000w |

|

weight |

200kg |